Mersey oil giant pushes on with carbon capture

EET Fuels appoints engineering experts to begin design work on project that will see 1m tonnes of CO2 a year from the Stanlow Oil Refinery captured and stored under Liverpool Bay. Tony McDonough reports

EET Fuels is moving a step closer to its goal of becoming the “first decarbonised oil refinery” in the world as it starts work on a carbon capture and storage project.

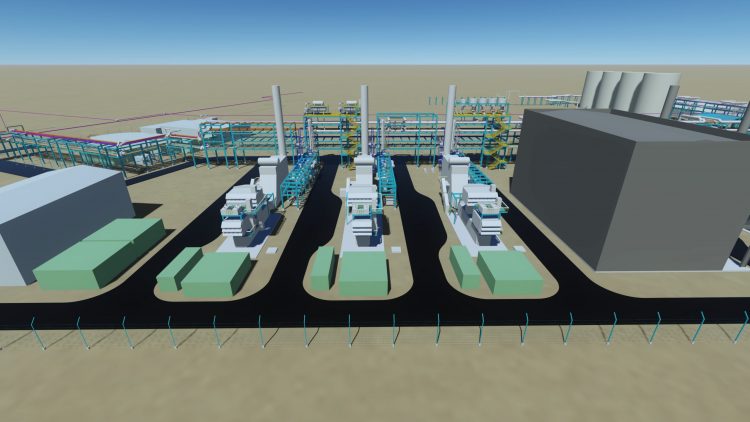

It has appointed Toyo Engineering India to progress to the front-end engineering design stage of the project that will see around 1m tonnes a year of CO2 from the Stanlow Oil Refinery close to the River Mersey captured and stored under Liverpool Bay.

Stanlow is the biggest emitter of CO2 in the region and currently pumps more than 2m tonnes a year into the atmosphere, contributing to global warming. This project, planned to be up and running by 2028, will capture and store around 45% of the total.

Furnaces are essential to an oil refinery. The process of refining crude oil means it has to be heated to around 470 degrees celsius. Stanlow’s ‘catcracker’ furnace is responsible for that 45%.

EET Fuels, the trading name of Essar Oil UK, has invested £45m in a new furnace which is now installed on the site. Although it can operate using conventional fuels it is also equipped to operate using hydrogen.

Stanlow will be the nerve centre of the multi-billion pound HyNet project which will produce hydrogen by burning natural gas and then store the emissions in depleted gas fields in Liverpool Bay. The hydrogen will be supplied to factories across the North West.

This method of hydrogen production is known as ‘blue hydrogen’ and there are many experts who are sceptical about the effectiveness of carbon capture. HyNet is awaiting a final decision on Government funding this autumn.

READ MORE: Stanlow could be ‘world’s first decarbonised refinery’

On the Stanlow site EET Fuels will have its own parallel project, which is part of the HyNet cluster. In August it appointed another firm, Wood, to design and build a fuel-switching system that will feed into the furnace.

Also in August another Essar subsidiary, Essar Energy Transition, acquired the 66-acre Thornton Science Park, adjacent to the refinery. This will be the location for the £3bn hydrogen and carbon capture hub.

Toyo, a subsidiary of the Toyo Engineering Corporation in Japan, will oversee design completion, project de-risking, and detailed costing analysis of the carbon capture element. This will enable EET to make a final investment decision.

It has also applied for the right to negotiate with the UK Government for a revenue support mechanism as part of the Department of Energy Security and Net Zero’s Track One expansion programme.

Deepak Maheshwari, chief executive of EET Fuels, said: “Our ambitious carbon capture and storage plans are a key component of Stanlow, securing the future of the refinery for generations to come and vastly reducing industrial carbon emissions in the North West.

“This announcement represents a significant milestone as we work to become the world’s first low carbon process refinery.”