How maritime firm boosted turnover 200% in four years

Stone Marine Shipcare in Wirral has been manufacturing and servicing propellers since Victorian times but a change in strategy in the last four years has seen it grow turnover by 200%. Tony McDonough reports

Back in 2019, Wirral-based Stone Marine, which operates on the banks of the River Mersey, took a hard look at its business model.

At that time 90% of its work installing, inspecting, maintaining, repairing, and modifying ships’ propellers was overseas.

Being a UK firm with a global reach wasn’t a bad thing, of course, but Stone felt it was missing huge opportunities in its domestic market and set about making a number of key changes in both strategy and personnel.

At this month’s Mersey Maritime Face-2-Face networking event in Birkenhead, Stone’s sales director, Gareth Gilbert, told an audience of maritime professionals and leaders how the business transformed its fortunes at home.

Gareth also talked about the rich history of the firm and how it has produced and maintained propellers for some of the biggest and most famous vessels in the world for nearly 200 years.

“We undertook a business review, and it became very clear that 90% of our work was outside the UK,” said Gareth. “So, we said OK, that’s great and we want that work to continue but we should be doing more within the UK’.

“So, we put a strategy in place and began to engage and get out of the front door, speaking to people and forming partnerships locally… that engagement with the local maritime community was invaluable.

“We also did more business development and we brought in new staff. Our website was overhauled and we developed social media profiles. That was key because it let the world know that we were still there.

“That reach out process is so important. We weren’t producing in the UK (its propeller manufacturing business (Stone Marine Propulsion) is now outsourced to the Far East), and many people took that to mean we were out of business altogether.”

However, just as Stone was making progress changing the overseas / UK work ratio COVID hit and its ability to send engineers to work overseas came to a halt almost immediately. For a few weeks Gareth said the situation was “terrifying”.

“80% of the work that was expected that year was gone,” he added. “But that process of building new relationships in the UK and overseas started to pay dividends. We plastered social media and kept the propeller repair workshop open.

“It ended up being the busiest ever period for our workshop. We told customers ‘We can’t travel to you but if you can get the propellers to us, we can fix them’.”

Even though Stone’s engineers couldn’t travel to the Far East to carry out our work, similarly rival firms in the Far East could not access Europe during the pandemic. The firm was able to carry out work on their behalf.

Although Gareth said there is still a post-COVID hangover with backlogs causing some disruption, the strategy first launched in 2019 has proved successful. Stone has kept its overseas work, but UK contracts now make up more than 60% and overall turnover is up 200%.

Gareth spoke about the history of Stone. Its roots go back to Josiah Stone in the 1830’s who began producing copper nails and rivets for shipbuilders in Deptford, London.

As the 19th century progressed and steam replaced sail as the primary propulsion method for ships and it was then that Stone really found its niche as a manufacturer of propellers. It cast its first bronze propeller blades around the 1890’s.

By the 1910s the business had established a global reputation and, for decades, produced propellers of all sizes for navies and merchant shipping operators all over the world.

It provided the propellers for HMS Ark Royal, built at Cammell Laird shipyard in Birkenhead in the 1930s. The firm also did work for famous cruise lines such as White Star and Blue Star.

By the start of World War II J. Stone & Co. and the Manganese Bronze & Brass Co. operated out of two sites – their original home in Charlton and in Deptford on the River Thames, London.

Both were seen as too vulnerable to Luftwaffe bombing raids, so some production relocated to Birkenhead.

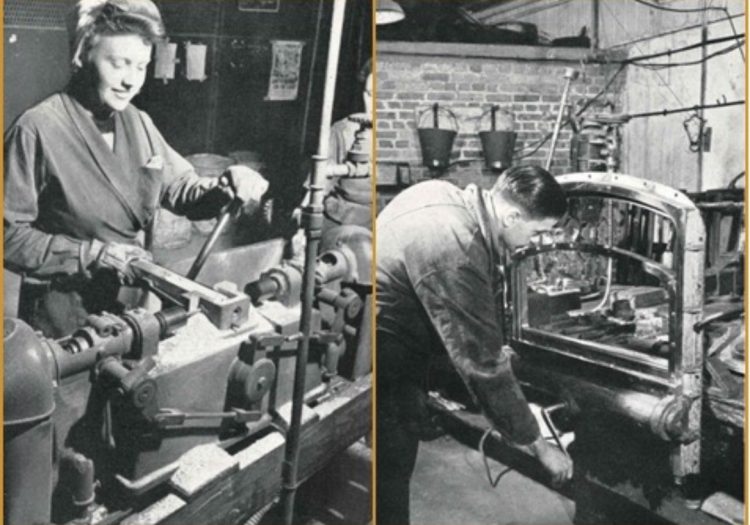

“With that move came an awful lot of innovation,” explained Gareth. “A lot of women came into the workforce and there was a change from heavy manual labour to increasing automation.

“We were casting in magnesium, and we produced billions of rivets, ships blast screens and we produced parts for aircraft including Mosquito’s and Lancaster bombers. And in six years, 22,000 propellers were manufactured which was a remarkable achievement.”

From the 1950s to the 1980s much shipbuilding capability moved to Asia though propeller casting continued in Birkenhead until just after the turn of the new millennium. Some of these propellers weighed as much as 100 tonnes.

In 2000, Stone’s Service Division was formally changed to Stone Marine Shipcare Ltd to become more focused on maintenance and repair.

Today Stone Marine Shipcare employs 10 people in Wirral, including five full-time propeller engineers as well as one consultant. It also draws on a wider network of engineers across the UK including 15 Service Engineers in Scotland.

Much of its maintenance and repair work, particularly on the bigger propellers, must be undertaken on site so its engineers can travel all over the world. Stone also has a presence in Turkey and Qatar and represents manufacturers in Japan & South Korea.

“Polishing, conditioning and modifying (for increased efficiency) propellers is something we do a lot of,” said Gareth. “These are jobs that look simple, but it is best to have professionals undertake the work.”

READ MORE: Starship looks to take on £4m Wirral Waters project

READ MORE: Peel Ports plans bigger turbines for Port of Liverpool

On the manufacturing side, Gareth added: “With our new propeller design, the NPT – New Profile Technology propeller, we can replace an older 100-tonne propeller with one around 30% lighter and improve efficiency by up to 6%. On a container ship that can use up to $50m of fuel a year, 6% is a big saving.”

And he said: “Over the past few years we have consolidated our position in the maritime community… we are investing in our workshop and in apprenticeships. We are a business with a truly global reach.”